The Zero-Waste Operation: Engineering Frictionless Growth and Operational Alpha

As the Chief Operational Architect at Elevion, my mandate is to view the enterprise not as a collection of departments, but as a single, complex, and highly sensitive system. The prevailing, anachronistic view of operational efficiency—a narrow focus on cost-cutting and headcount reduction—is a fiduciary failure. It addresses symptoms, not the systemic pathology that truly impedes non-linear growth. The modern C-suite must recognize that the largest single impediment to scale is not external market friction, but the internal, hidden tax of systemic entropy.

I. The Hidden Tax of Systemic Entropy

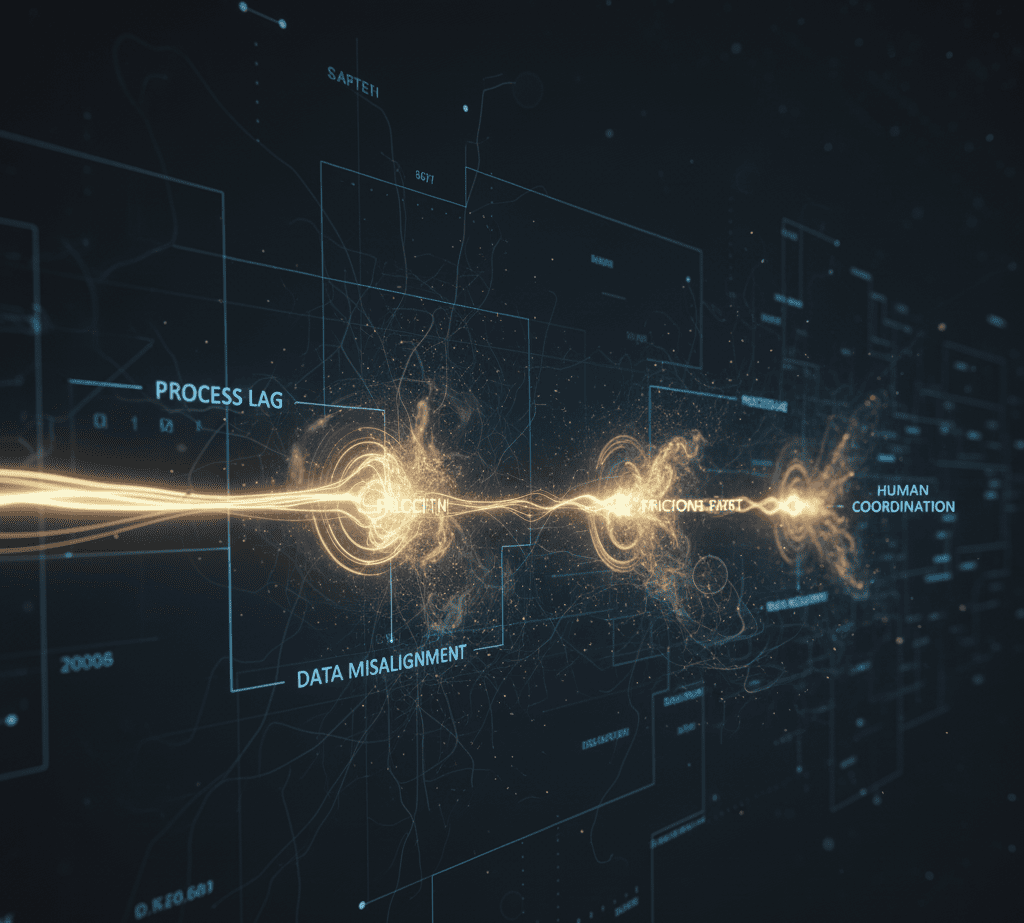

Systemic entropy is the natural, inevitable decay of efficiency within any complex organization. It is the energy lost in the transfer of information and resources across functional boundaries. This operational waste is not the visible overhead of excess inventory or redundant personnel; it is the process covariance—the non-linear drag created by misaligned handoffs, asynchronous data states, and the constant need for human-in-the-loop coordination.

This friction tax is a silent, compounding liability on the balance sheet. It is the time-delay between a sales order and a fulfillment trigger; the manual reconciliation required due to disparate data taxonomies; the executive bandwidth consumed by mediating inter-departmental conflicts. Each point of friction introduces operational drag, which directly reduces the firm’s velocity and, critically, caps its potential for non-linear growth. A system with high entropy can only scale linearly, as every increase in volume necessitates a proportional, or even exponential, increase in coordination effort. True efficiency, therefore, is not about minimizing input, but about maximizing systemic flow to eliminate this internal drag.

II. Operational Alpha: The Source of Unreplicable Edge

The objective of the Zero-Waste Operation is to generate Operational Alpha—a structural efficiency advantage that is non-replicable by competitors. Operational Alpha is not achieved through incremental optimization; it is achieved by architecting self-optimizing loops.

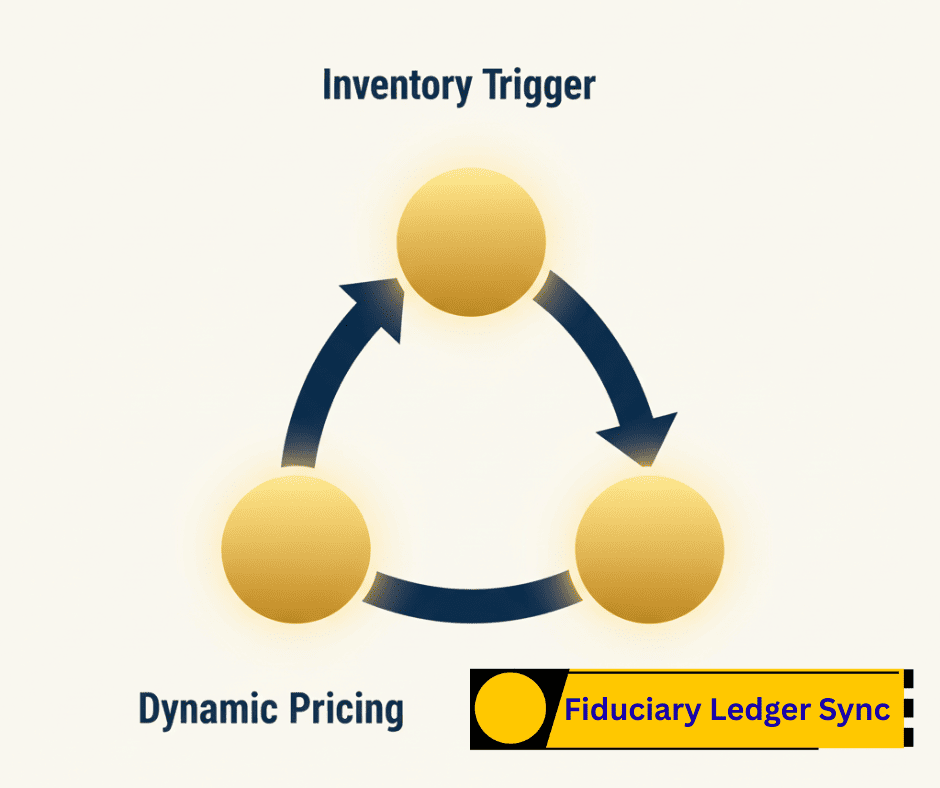

A self-optimizing loop is a closed-loop system where the output of one process perfectly and automatically serves as the input for the next, eliminating the need for human intervention or manual reconciliation. This is the modernized, scientific application of Lean principles, moving beyond simple waste reduction to systemic flow. For example, in a high-velocity supply chain, a self-optimizing loop might involve:

- Inventory Depletion Trigger: Real-time sales data automatically triggers a re-order from a pre-vetted supplier.

- Dynamic Pricing Adjustment: The re-order event, coupled with predictive demand modeling, automatically adjusts the forward-looking pricing algorithm to optimize margin and inventory turnover

- Fiduciary Reporting: The entire transaction sequence is instantly and immutably recorded in the general ledger, eliminating end-of-period reconciliation.

This architecture eliminates human-in-the-loop drag, converting process efficiency into a constant, compounding competitive weapon. Operational Alpha is the structural moat that competitors cannot cross, as it is embedded deep within the firm’s proprietary systems and process architecture, not merely its product or service offering. It is the conversion of systemic rigor into frictionless growth.

III. The Three Dimensions of Operational Waste

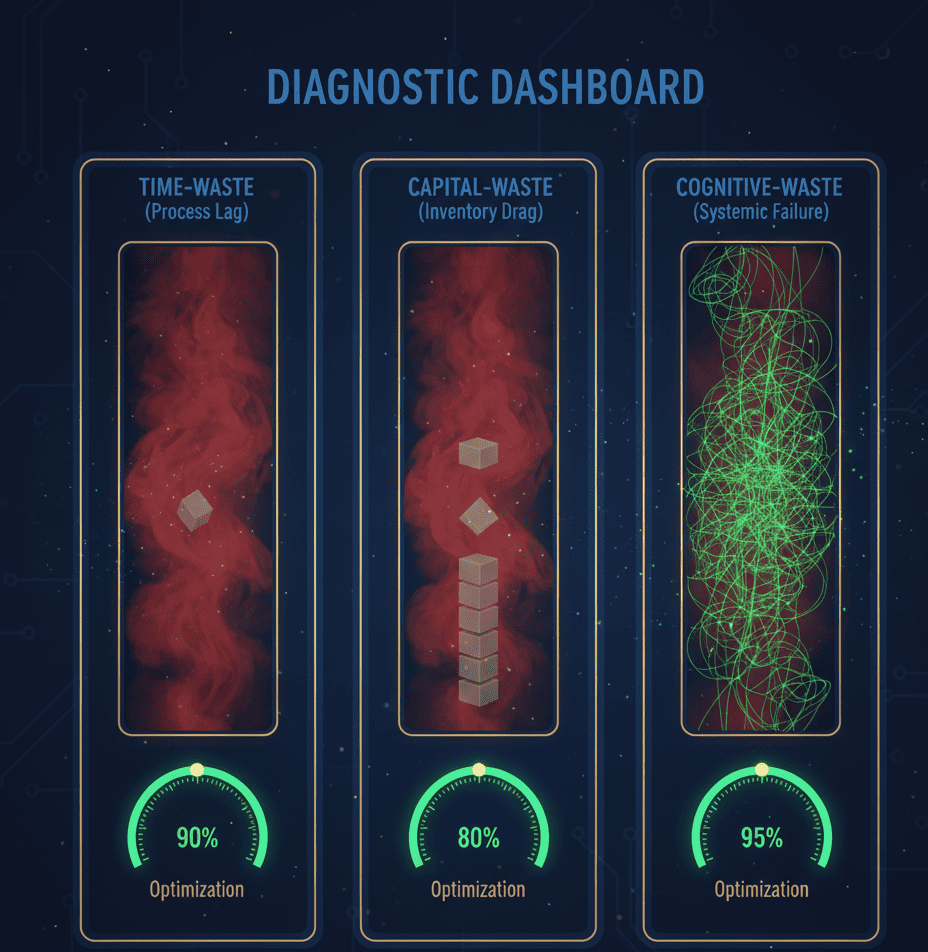

To successfully engineer a Zero-Waste Operation, the Chief Operational Architect must systematically hunt and neutralize waste across three critical dimensions. This requires a shift in perspective, viewing waste not as a resource problem, but as a systemic failure that must be quantified and eliminated.

| Dimension of Waste | Definition and Impact |

| 1. Time-Waste (Process Lag) | The systemic delay between the completion of one process and the initiation of the next. This is the primary source of operational drag and is often hidden in approval queues and manual data transfers. |

| 2. Capital-Waste (Inventory Drag) | Capital that is physically or digitally static, failing to generate a return. This includes excess inventory, non-performing assets, and data silos that prevent real-time decision-making. Maximize Liquidity: Implementing just-in-time systems and real-time data integration to ensure capital is always in motion and generating alpha. Cognitive-Waste (Systemic Failure) |

| 3. Cognitive-Waste (Systemic Failure) | The intellectual capacity of high-value employees consumed by solving repetitive, systemic failures (e.g., fixing broken reports, manually correcting data errors, mediating process conflicts). |

The fiduciary responsibility is to ensure that every unit of time, capital, and cognitive resource is deployed to maximize its risk-adjusted return. By quantifying and eliminating these three dimensions of waste, the organization moves closer to a state of systemic flow, where growth is no longer a struggle against internal friction, but a natural consequence of a well-architected system.

IV. Conclusion: Building the Self-Optimizing Enterprise

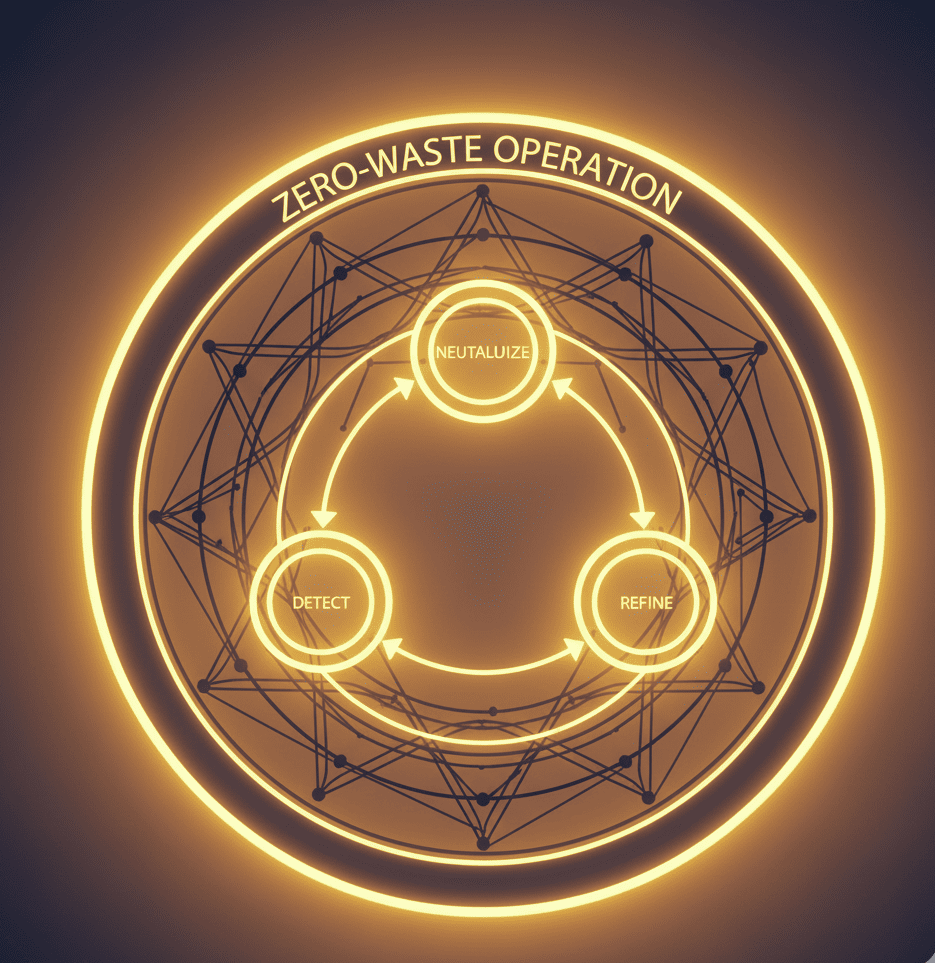

The ultimate goal of the Zero-Waste Operation is not efficiency as a finite project, but as a permanent, self-correcting system. This is the self-optimizing enterprise—a firm where the architecture itself is designed to detect and neutralize systemic entropy before it can manifest as operational drag.

This requires a commitment from the C-suite to invest in the underlying process architecture with the same rigor they apply to product development. The firm’s operational model must be treated as a strategic asset, constantly monitored, measured, and refined. When this systemic rigor is achieved, the organization converts operational excellence into a constant competitive weapon, ensuring that growth is not only accelerated but is also fundamentally de-risked. The Zero-Waste Operation is, in essence, the CEO’s guide to frictionless growth—a system that guarantees that every unit of market opportunity is captured with maximum velocity and minimum internal resistance.