Finding Alpha in Your Supply Chain: Transforming Logistics from Cost Center to Competitive Edge

As the Chief Supply Chain Engineer at Elevion, my perspective is clear: the supply chain is not a cost center to be minimized, but the most powerful, yet often untapped, source of Operational Alpha within the enterprise. The traditional view of logistics as a necessary, reactive function is a fiduciary failure that exposes the firm to unacceptable levels of risk and capital waste. The modern supply chain must be engineered as a self-optimizing competitive weapon.

I. The Unacceptable Cost of Inventory Drag

The fundamental flaw in conventional financial modeling is the classification of inventory as a benign asset. In reality, inventory is often capital locked in operational stasis, a physical manifestation of Capital-Waste. The true cost of inventory is not merely its carrying cost, but the compounding liability of inventory drag and demand mismatch risk.

Inventory drag is the systemic friction created by static capital. It extends the cash conversion cycle, increases warehousing costs, and, most critically, exposes the firm to obsolescence risk. The traditional approach to managing this risk is reactive inventory—relying on historical data and generalized forecasting models. This is a system built on prediction, which is inherently flawed and high-variance.

Elevion’s methodology contrasts this with predictive inventory—a system built on real-time demand signaling. In a predictive system, inventory policy is not dictated by a historical forecast, but by the instantaneous, granular signal of consumer demand. This shift transforms inventory from a static asset into a dynamic, flowing resource, minimizing the time capital remains in stasis and dramatically reducing the Marginal Cost of Friction (MCF) across the logistics network. The goal is not to have less inventory, but to have the right inventory in the right node at the exact moment of need.

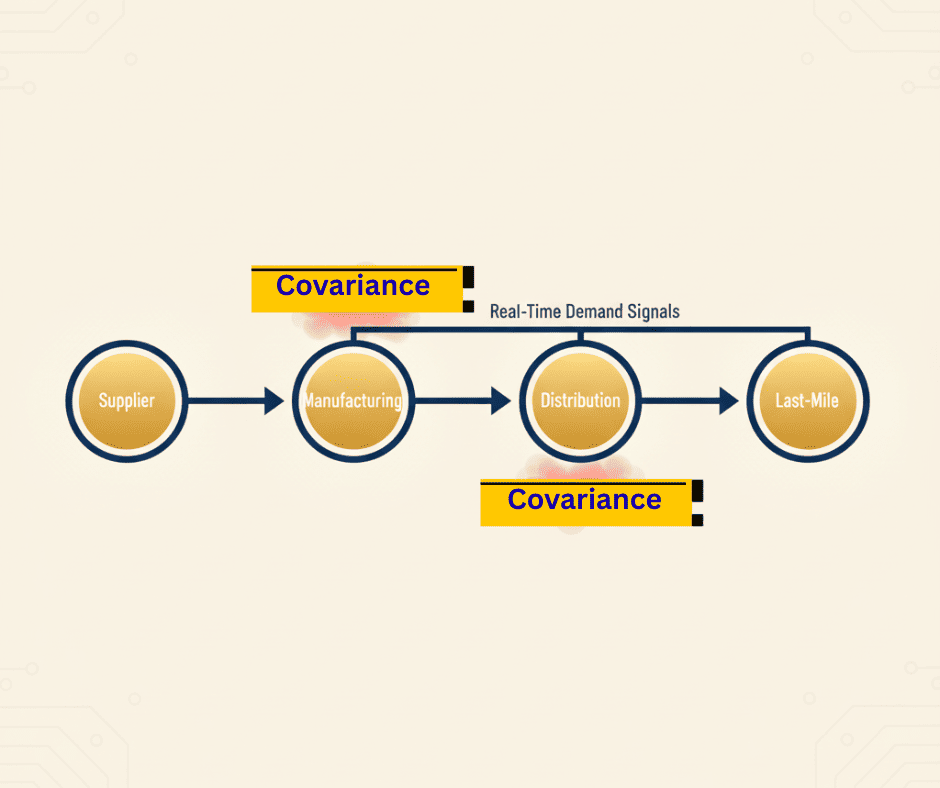

II. The Architecture of Flow: Eliminating Logistics Covariance

Operational Alpha in the supply chain is found by eliminating logistics covariance—the systemic friction between different supply chain nodes (supplier, manufacturing, distribution, last-mile). This covariance is the primary source of Time-Waste and Systemic Entropy, manifesting as delays, expedited shipping costs, and manual reconciliation efforts.

Eliminating this covariance requires building a single, integrated Causal Flow Map that dictates inventory and production policy. This map is not a simple diagram; it is a proprietary algorithm that models the interdependencies of the network and identifies the high-friction handoffs.

The architecture of flow mandates that the system must be governed by a single source of truth: real-time consumer demand signals.

- Demand-Driven Production: Manufacturing schedules are not based on a monthly forecast, but are dynamically adjusted by the instantaneous rate of consumption. This creates a self-optimizing loop where the output of the sales process perfectly feeds the input of the production process, eliminating the friction of manual scheduling.

- Node Synchronization: Each node in the network (e.g., a regional distribution center) operates not as an independent entity, but as a synchronized component of the whole. Inventory policy at the distribution center is dictated by the inventory level and consumption rate of the last-mile delivery hub, eliminating the need for buffer stock and the associated Capital-Waste.

By engineering the supply chain for zero-drag flow, the firm converts its logistics network from a series of high-friction, siloed processes into a single, cohesive, and highly responsive system.

III. Supply Chain as a Risk Hedge

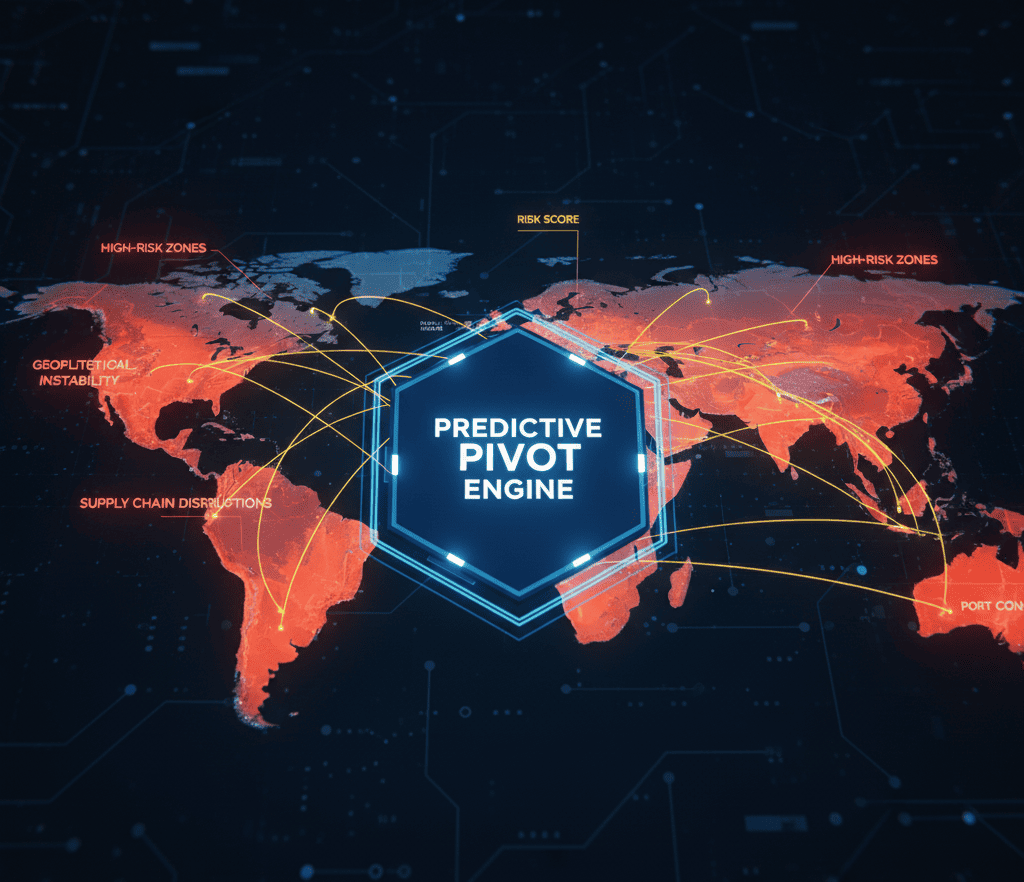

A high-Alpha supply chain is not merely an engine for efficiency; it is a powerful risk hedge against external shock. In an era defined by geopolitical friction, climate volatility, and raw material scarcity, a supply chain built on single-source dependency and static routing is a structural liability.

Elevion achieves this defensive value through two core architectural mandates:

- Network Topology Optimization: The network is designed not for the lowest average cost, but for the highest Systemic Elasticity. This involves strategically mapping multiple, redundant pathways for critical materials and finished goods. The system is constantly modeling the cost and risk profile of every possible route and vendor, allowing for instant, automated pivot. This ensures that a disruption in one node does not cascade into a systemic failure.

- Predictive Risk Modeling: The system integrates real-time, non-traditional data (e.g., geopolitical stability indices, weather patterns, commodity market volatility) to generate a predictive risk score for every vendor and route. When a risk score exceeds a pre-defined threshold, the system automatically triggers a shift to a lower-risk, pre-vetted alternative.

This approach transforms the supply chain from a passive recipient of external shock into an anti-fragile system that gains strength from disorder. The ability to pivot vendors or routes instantly, based on predictive intelligence, is an unreplicable structural advantage that insulates the firm from the high-variance costs of market disruption.

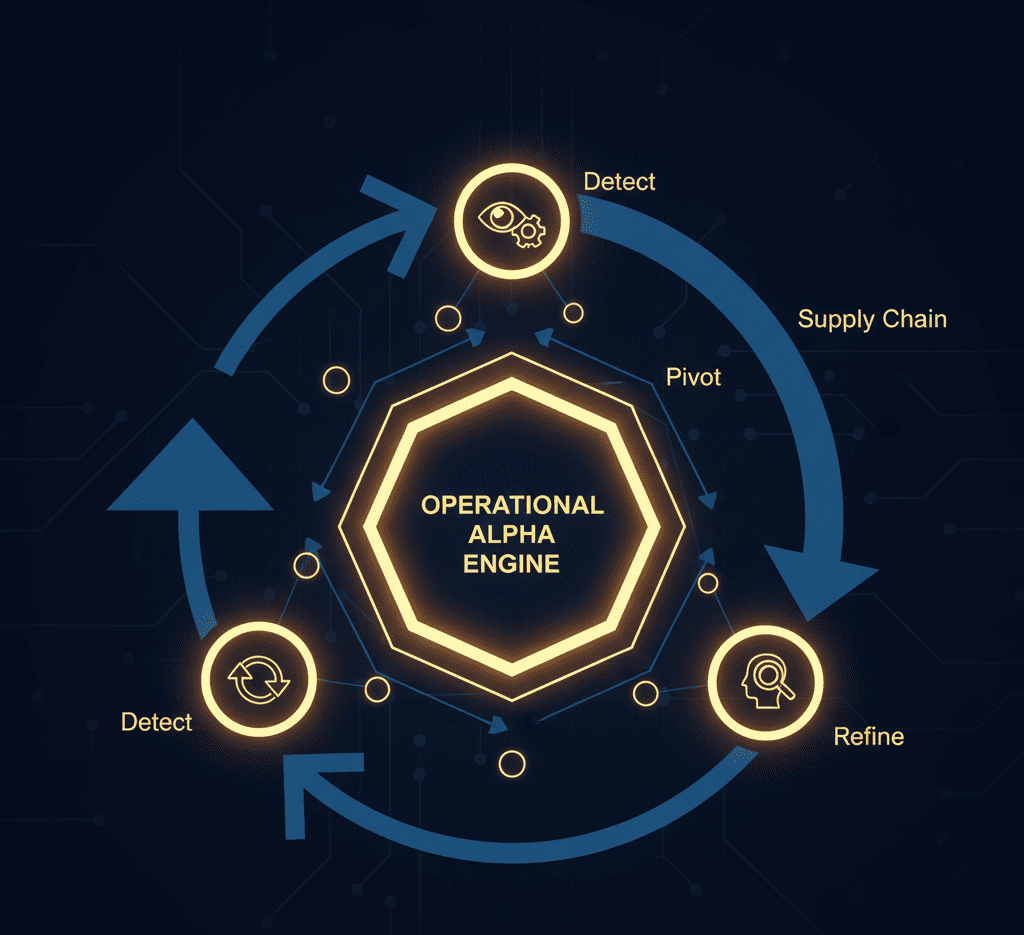

IV. Conclusion: The Self-Correcting System

The modern supply chain must be a self-correcting system where every node anticipates and reacts to market changes with algorithmic precision. The era of the reactive, cost-focused logistics function is over. The future belongs to the firm that recognizes that the supply chain is the ultimate laboratory for Operational Alpha.

By eliminating inventory drag, logistics covariance, and systemic risk through predictive intelligence, the firm converts its logistics efficiency into an unreplicable structural advantage. This is the only path to ensuring that growth is not only accelerated but is also fundamentally de-risked from the volatility of the global market.